More than 40 years of effort to achieve submicrometer accuracy

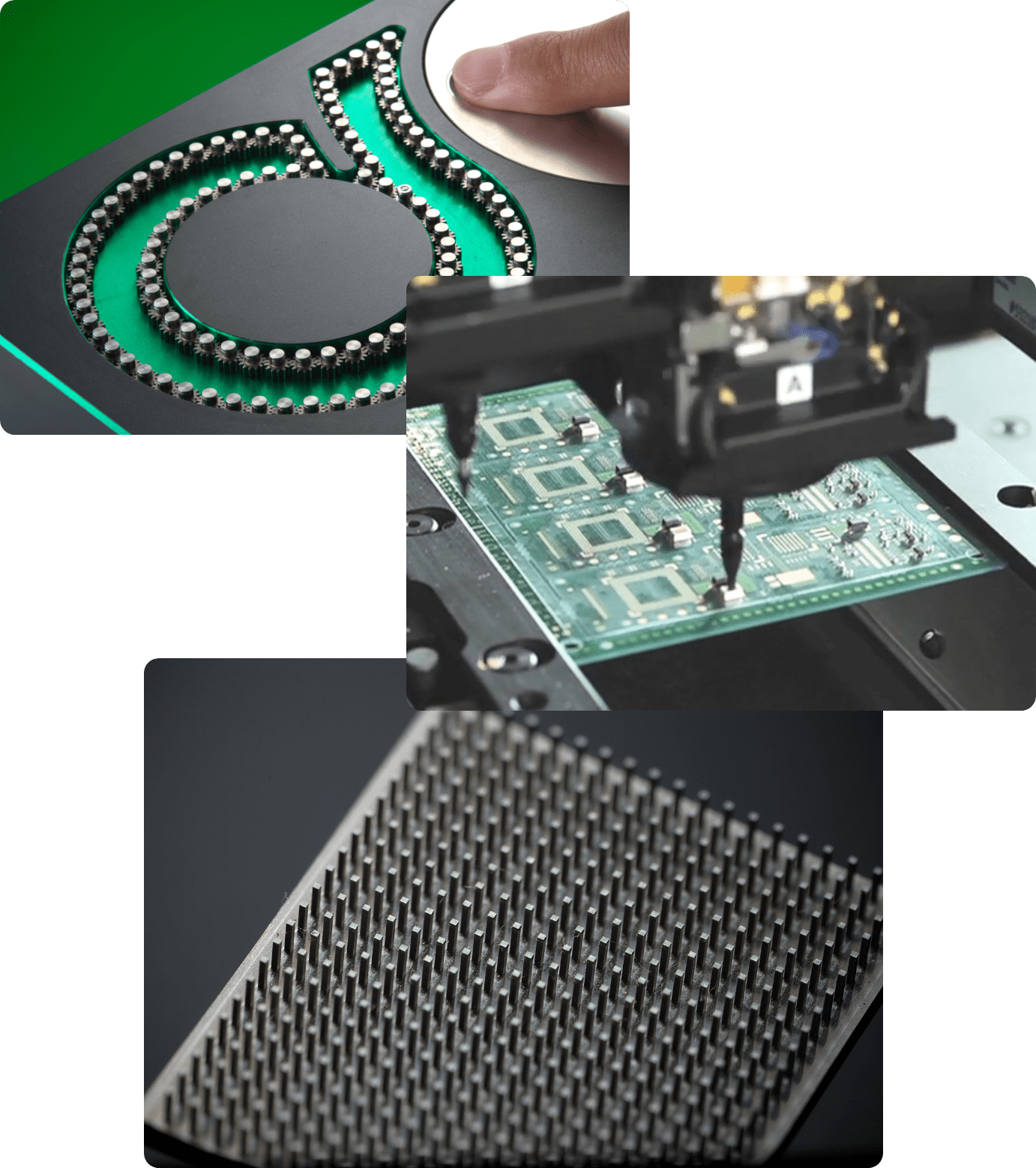

Our main businesses are the precision machining of the automobile, robotics, electronic SMT mounter, medical, gear, and machinery parts. We are capable of any orders from Prototype, Single piece, High-mix & Low-volume to Mass-production parts with one-stop solution by our optimized production system and thorough quality management system. We also focus our effort on the complicated system assembly of precision parts to meet a wide range of our customers’ needs. We are fully equipped with engineering and manufacturing skills to fulfil our customers’ request and to achieve our customers’ QCD goals.

Industries Served

-

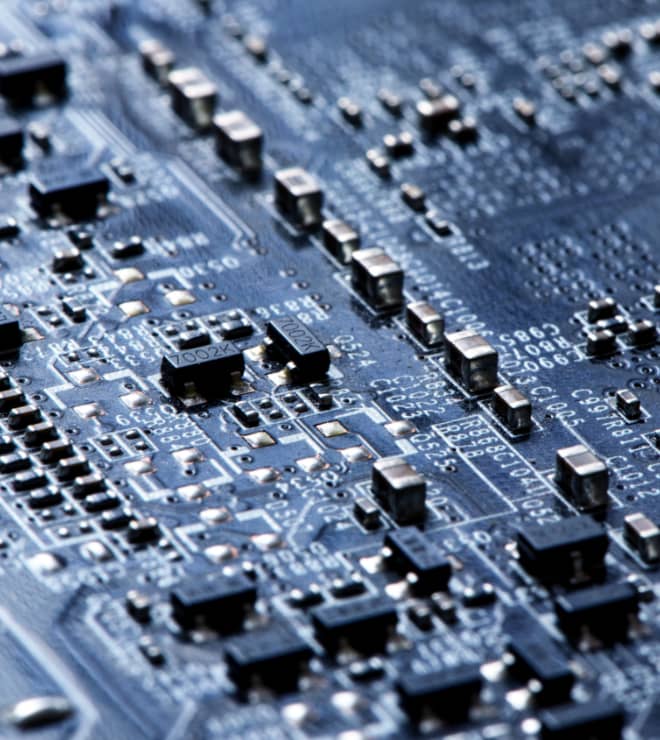

![SMT mounter]()

SMT mounter

-

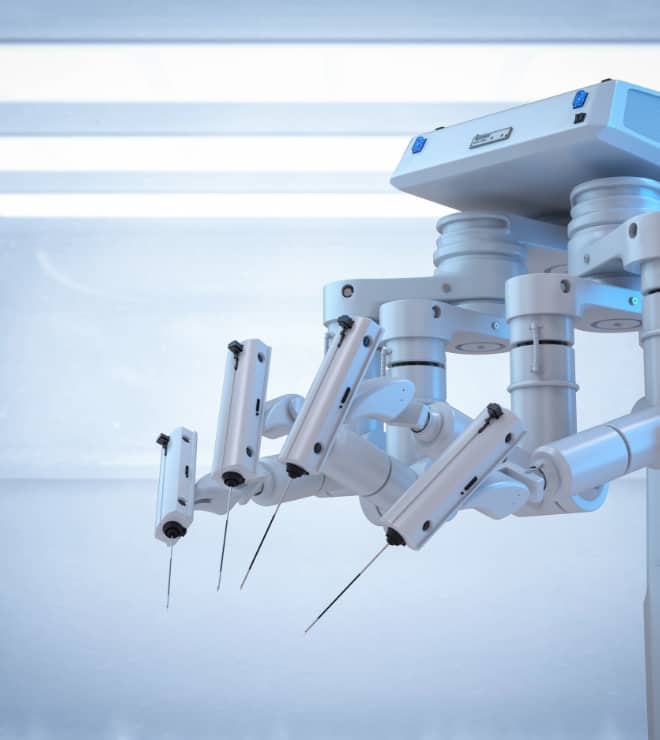

![Medical]()

Medical

-

![Robotics]()

Robotics

-

![Automobile]()

Automobile

Technology

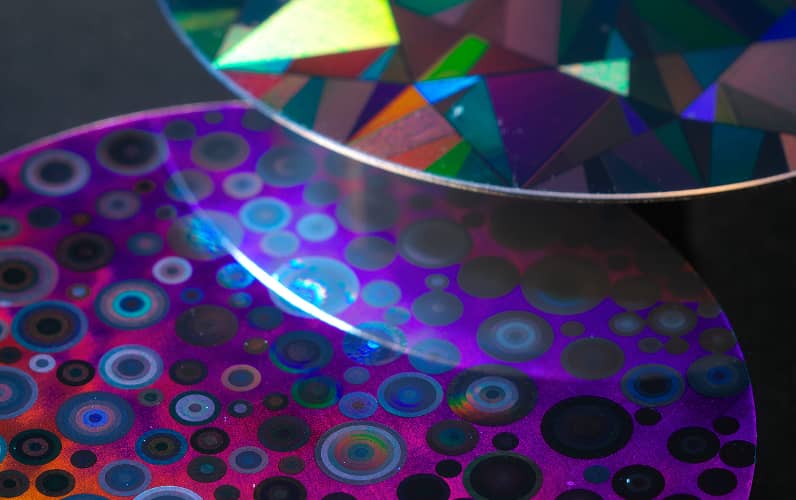

LASER TECHNOLOGY

Based on the laser microfabrication technology, we propose the less heat effect functionality addition on the metal surfaces by using short pulse lasers. For example, our technology can implement non-reflective black surface without applying paint or chemicals, rust removal, antibacterial effects, water repellent effects, and stained glass-like color effect, etc.

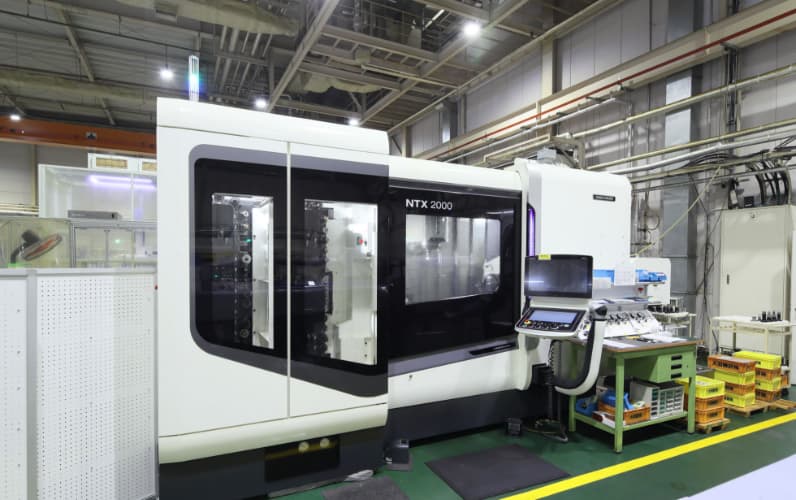

MILLING/TURNING TECHNOLOGY

Our milling/turning technology focuses on the small parts, light weight parts, hardened parts, and high precision parts featuring the complicated shapes, multifaceted shapes, and difficult-to-cut-materials with tight geometrical tolerances by utilizing 5-axis MCs, Automatic lathes, and Multi-axis machines, etc.

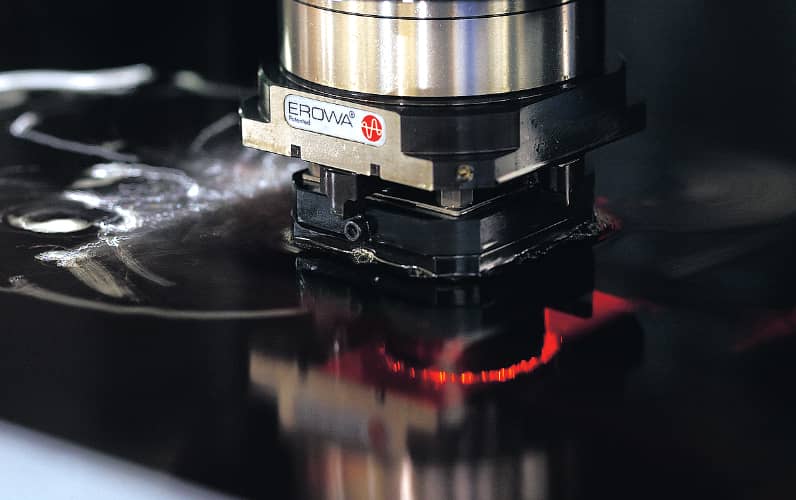

Grinding Technology

Our main business started with precision grinding. Over 40 years, our strength has been demonstrated by precision grinding of easily distorted parts such as thin/slender parts with strict tolerances by utilizing Cylindrical Grinders, Inner Grinders, and Surface Grinders. We can also solve all of our customers’ problems by utilizing distinctive equipment such as Jig Grinders, Tool Grinders, and Centerless Grinders, etc.

EDM Technology

Using our know-how and cultivated technology, successful application of wire-cut and die-sinker electrical-discharge machining (EDM) on the machining of parts has been demonstrated. More difficult shapes, precision, and machining on difficult-to-cut materials can be achieved by using our EDM, in addition to other traditional machining process.

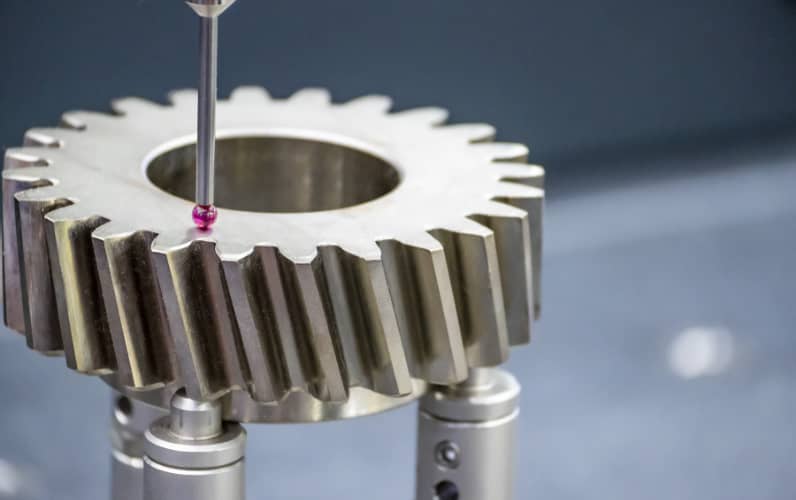

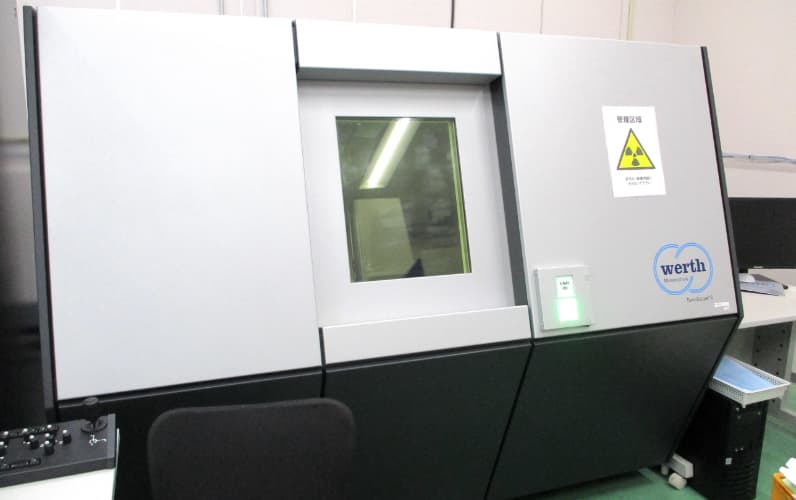

Measuring Technology

Precisely machined parts demonstrate their performance after they are precisely measured. We are fully equipped with various precision measuring instruments such as CMM, Contour Measuring Machines, Optical Profilers, etc. We are also equipped with SEM and EDX for analysis of surface textures and constituent elements. Further, we have introduced an X-ray CT Scanning Machine to reduce lead time while ensuring measurement quality.

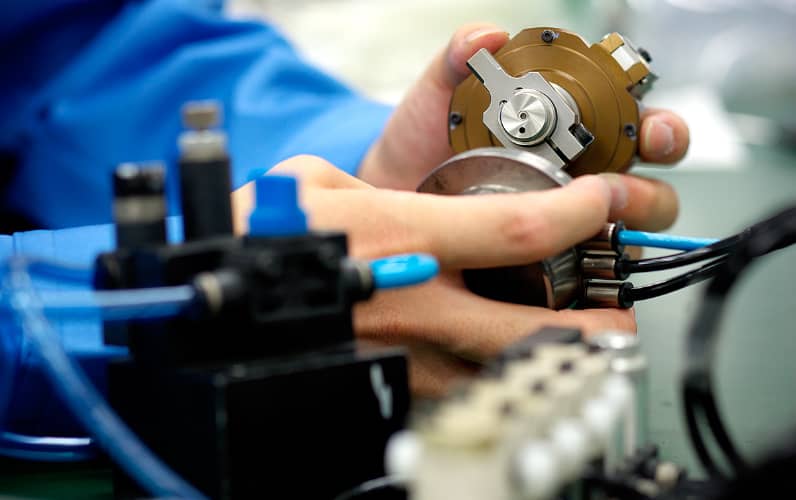

Assembly Technology

Precisely machined components must be precisely assembled as a device to fully exhibit its performance. We do not only machine the parts but also assemble these parts and do the function tests of the assembled devices, which we believe contributes to our customers’ benefits. We also enhance the assembly work automation for the advancement of the accuracy assurance and lead time reduction.

Main equipment

STUDER Universal Grinder

s41-1000

NAGASE INTEGREX Surface Grinder

SGC-630αS4-ZERO4

HAUSER Jig Grinder

S45-400

DMG MORI Multi-axis Mill Turn center

NTX2000

Matsuura 5-axis Machining Center

MAM72-35V

DMG MORI 5-axis Machining Center

NMV3000 DCG

YASDA Vertical Machining Center

YBM-950V

WALTER Tool Grinder

HELITRONIC POWER-W

Carl Zeiss CMM

PRISMO Navigator

Werth X-ray CT Scanner

TomoScope S

ZYGO 3D Optical Profiler

New View

Hitachi Scanning Electron Microscope

S-3400N

Gallery

Laser micro cut parts assembly sample

- Material :

- AISI 304

- Size :

- 1.5mm

- Features :

- Assembled from 9 thin plates

Laser micro cut characters and logo

- Material :

- AISI 304

- Size :

- 0.12mm / Thickness 0.02mm

- Features :

- 0.025mm width at the narrowest part

Laser micro decoration sample

- Material :

- AISI 304, NSS431DP-2, etc.

- Features :

- Stained glass-like color effect

Planetary gear assembly

- Material :

- AISI 420 and acrylic resin

- Size :

- φ77mm

- Features :

- Assembled from over 70 parts

- Process :

- Gear grinding, EDM, Laser machining, Assembly, etc.

Small & silent gear grinding sample

- Material :

- AISI 420, 440C, etc.

- Size :

- ≥ Module 0.15 plain gear

- Features :

- Improve the accuracy and strength, and to reduce noises

- Process :

- Gear grinding

Gear integrated slide shaft

- Material :

- AISI 440C

- Size :

- φ5mm x 80mm / Module 0.15 plain gear

- Accuracy :

- Tolerance ≤ 1μm / Straightness ≤ 1μm / Roundness ≤ 1μm

- Process :

- Gear grinding, Centerless grinding, Assembly, etc.

Polygon grinding sample

- Material :

- AISI 420

- Size :

- φ30mm x 80mm

- Accuracy :

- Eccentricity ≤ ±5μm / Cam profile ≤ 0.03mm

- Process :

- Cylindrical grinding

Carrier

- Material :

- AISI 440C

- Size :

- φ75mm

- Accuracy :

- Tolerance ≤ 3μm / Position ≤ 2.5μm

- Process :

- Jig grinding

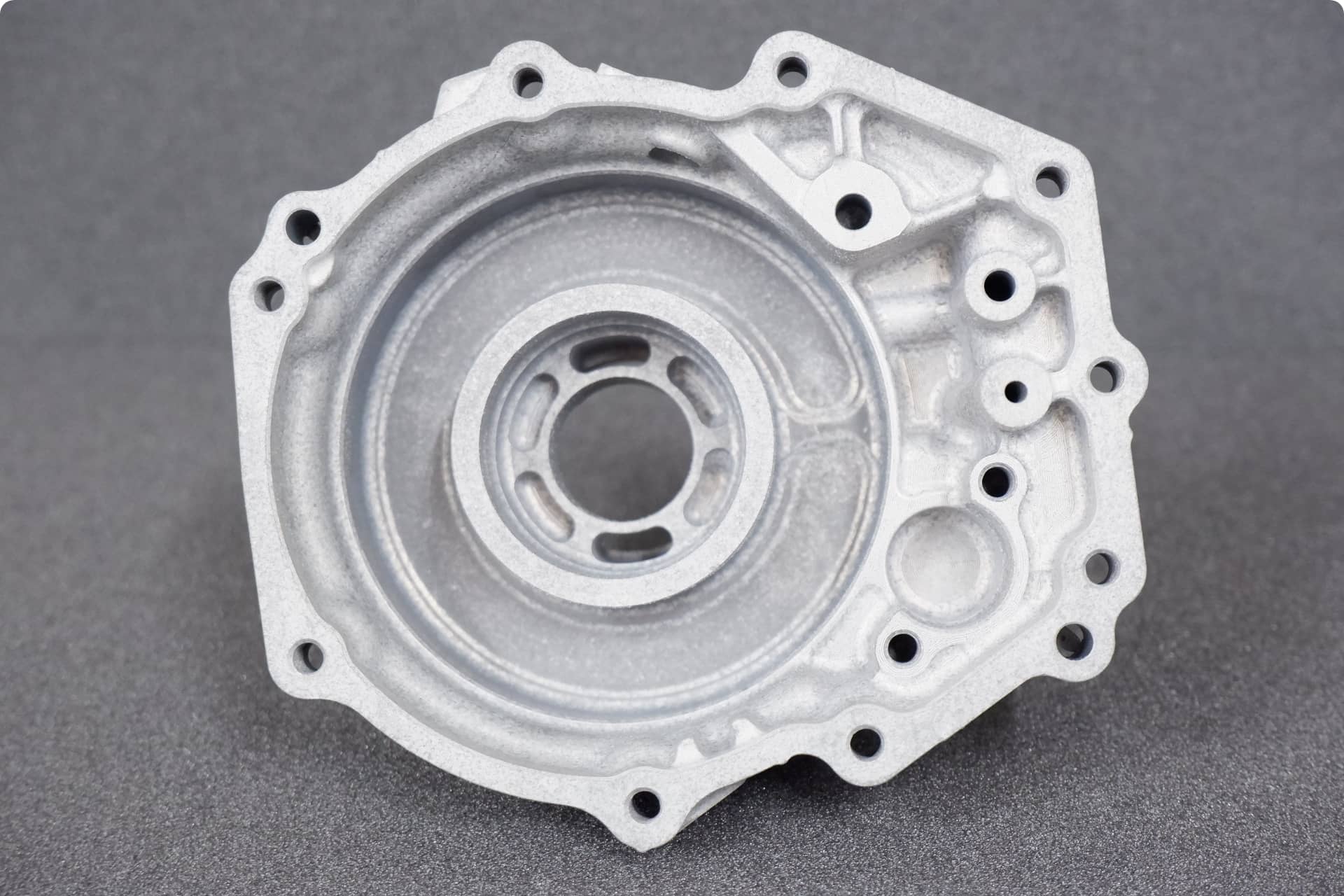

Transmission case

- Material :

- Magnesium alloy

- Features :

- Light weight and high damping capacity

- Process :

- 5-axis machining

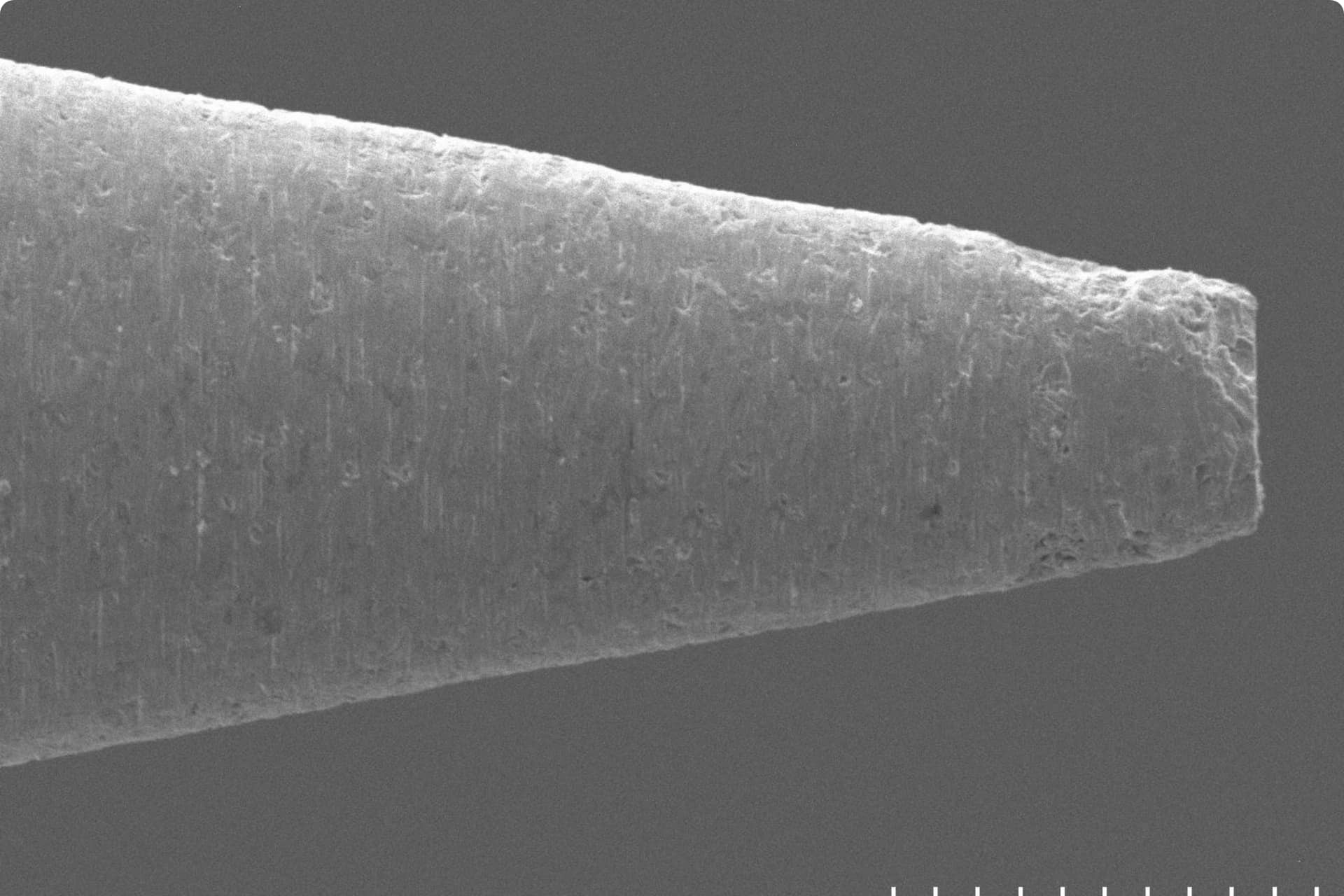

Carbide probe

- Material :

- Micro-graincemented carbide(SA220)

- Size :

- Tip diameter φ6μm

- Process :

- Tool grinding

Formed tools

- Material :

- Carbide, CBN, HSS, Ceramics, etc.

- Size :

- ≥ φ0.025mm

- Features :

- For complex holes, inner grooves, etc.

- Process :

- Tool grinding

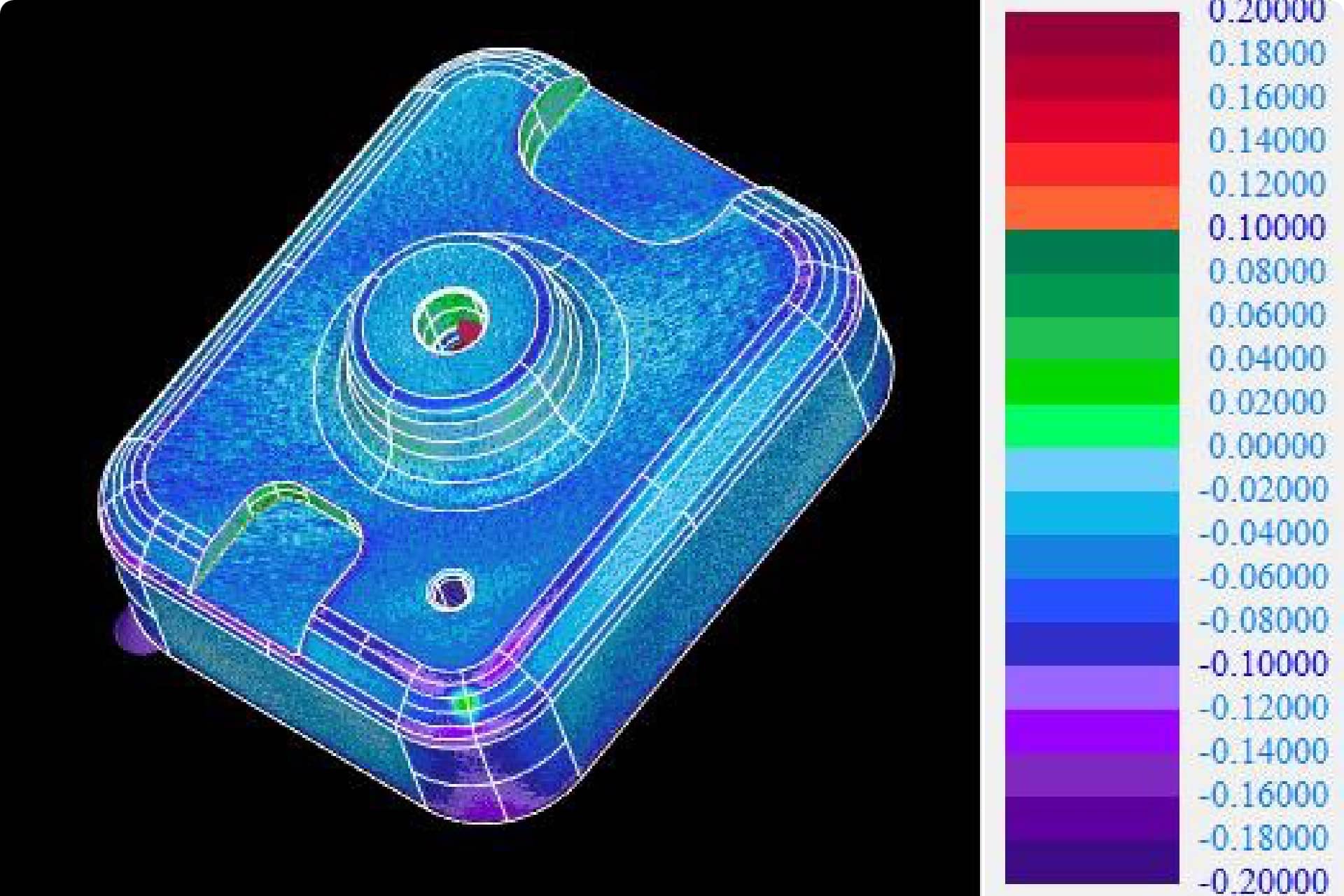

X-ray CT scan measurement sample

- Load capacity of the equipment :

- ≤ 15kg

- Position resolution :

- 0.1μm

- Features :

- Actual dimension measurement and CAD comparison measurement

- Process :

- X-ray CT Scan

ABOUT US

- Company Name

- OHBA SEIKEN Co., Ltd.

- Foundation

- April 1973

- Capital

- 30million JPY

- Representative

- Chief Executive Officer - Takumi Fujii

- Address

- 170 Aza-Fukazawa, Terasawa-cho,

Toyohashi-shi, Aichi 441-3124, Japan - Number of Employees

- 253 (as of March 31, 2020)

- y-mori@ohba-seiken.co.jp

QUALITY MANAGEMENT

We are ISO9001:2015 & ISO13485:2016 certified.

Not to mention in-coming and pre-shipment inspection, we thoroughly control the working environment and

thoroughly

perform the in-process inspection in order to establish quality of the product, accuracy of the machine,

and skills of

our team members.

For each order, production control document (Process chart and production drawings) is prepared for the

production

identification and the process traceability purpose. In-process inspection records at each process and

final inspection

records are stored together with the production control document at the completion of all process.

FAQ

Production Lot

What is your production capacity?

From one trial parts to mass production 100,000 parts/month

Quote/Budget

How long does it normally take to respond to RFQ?

Trial parts : We will response within 24 hours

Production parts : Please feel free to ask us.

I don’t have any drawings but I’d like to have a rough quote.

Any description about the parts (Sketches, sizes, etc.) is ok for us to prepare quote.

I have a limited budget for procurement.

We can offer proposal to meet your budget.

Lead Time

What is your standard lead time?

Machining : 1 or 2 weeks after PO.

Machining + Grinding + Heat treatment : 3 or 4 weeks after PO.

Materials

What materials are applicable?

Stainless steel 420, 440, 316L, 303, etc.

Aluminum alloy A2017, A5052, A6061, etc.

Chrome molybdenum steel 4115, 4120, 4135, etc.

Bearing steel, Die steel, Tool steel, Carbon steel, Alloy steel, etc.

Pure titanium, Titanium alloy, Superhard alloy, Carbide, Zirconia, Magnesium alloy,

PEEK resin, Polyacetal resin, etc.

Are medical grade materials applicable?

Just please let us know the material specification.

Are ASTM materials applicable?

Just please let us know the material specification.

Capability

What kind of machining you can do?

Milling : Simultaneous 5-axis, high-speed, off-axis parabolic, contouring/profiling, slender holes,

etc.

Lathe : Turning, end face, flat face, 5-axis, etc.

Non-grinding machining, drilling, tapping, gear cutting, gear skiving, EDM (Micro-holes, slit, inner

gear)

What kind of grinding you can do?

ID/OD grinding, gear grinding, taper grinding (Minimum φ0.001” tip dia.)

Non-cylindrical grinding (Polygon, cam, etc.)

Surface grinding, center-less grinding, 5-axis grinding

Applicable shapes?

Any complicated shapes are ok.

I need small thread screws or non-standard threads screws.

We have experience with S0.6 threads. In case if the thread specification is unknown, just please ask us, we can measure the parts with our device and can distinguish it. If the applicable tool is not found, we can prepare “home-made” threading tools.

Applicable sizes?

Milling/EDM : up to 11.8”x11.8”x11.8” for blocks, up to 23.5”x15.7” for plates, holes from

φ0.0012”(depth

up to 10D)

Lathe : up to φ7.8”x15.7”

OD grinding : φ0.04” to φ11.8” (Length up to 19.7”)

ID grinding : φ0.04” to φ7.8” (Length up to 7D)

Surface grinding : up to 23.5”x15.7”

Gears : from m0.15

Can you do any surface treatment or heat treatment?

Quenching, Tempering, Carburizing, Nitriding, Plating, Anodizing, Chrome plating, Painting, Laser marking, etc.

How about polishing and finishing?

Aero lapping, Iepco treatment, Barrel polishing, Honing, Lapping, Electro chemical deburring, Electrolytic polishing, etc.

Other applicable manufacturing process?

Assembly, press-fit, Automation, etc.